I disassembled and reverse engineered every part of this Showa motorcycle shock. Autodesk Inventor Pro was used for parametric modeling and drafting.

I built this grinder vise assembly with Autodesk Inventor Pro and made functional constraints in the assembly, as shown in the video below.

Autodesk Inventor - Showing mechanical movements of grinder vise parts

This is a diesel piston that has been fully modeled and detailed in Autodesk Inventor Pro.

Autodesk Inventor - Showing Section views of a caterpillar piston

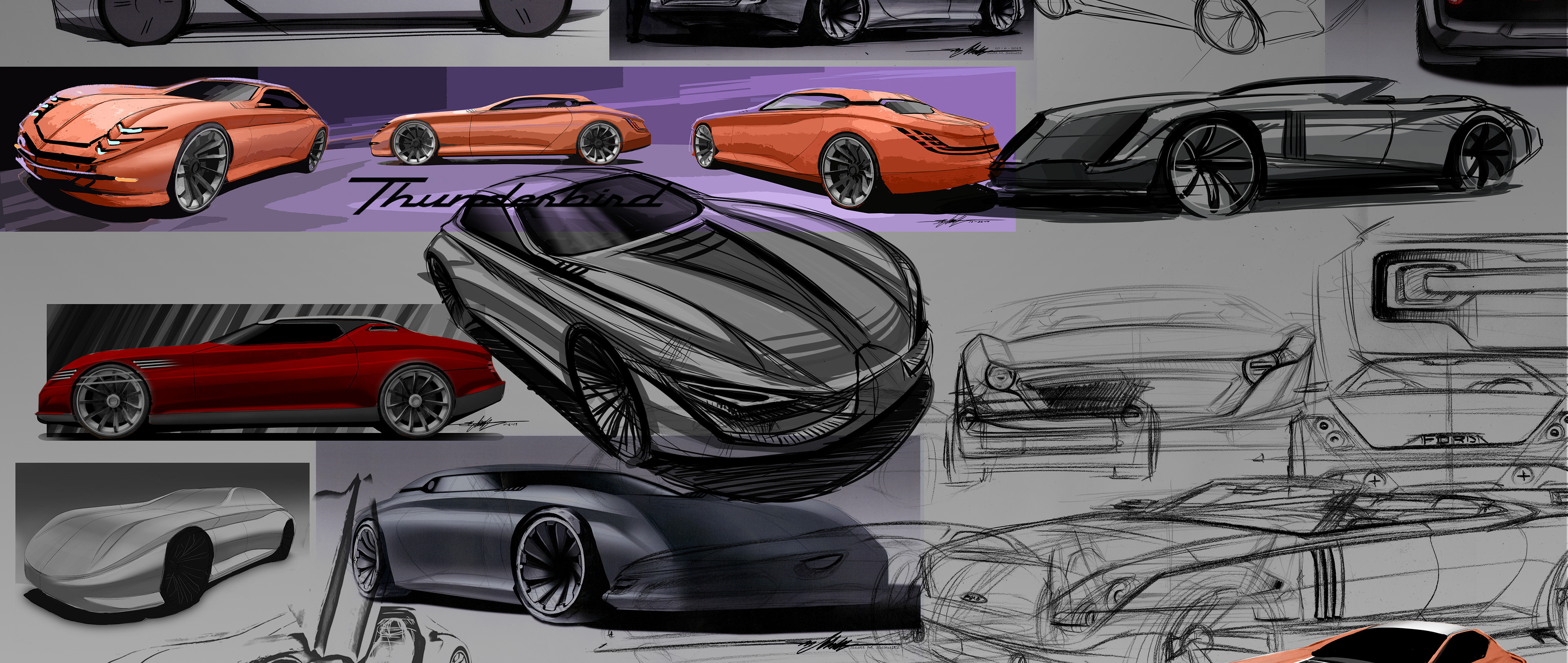

Below is a couple personal applications to a customers vehicle that I designed, 3D modeled in Autodesk Inventor Pro, and fabricated.

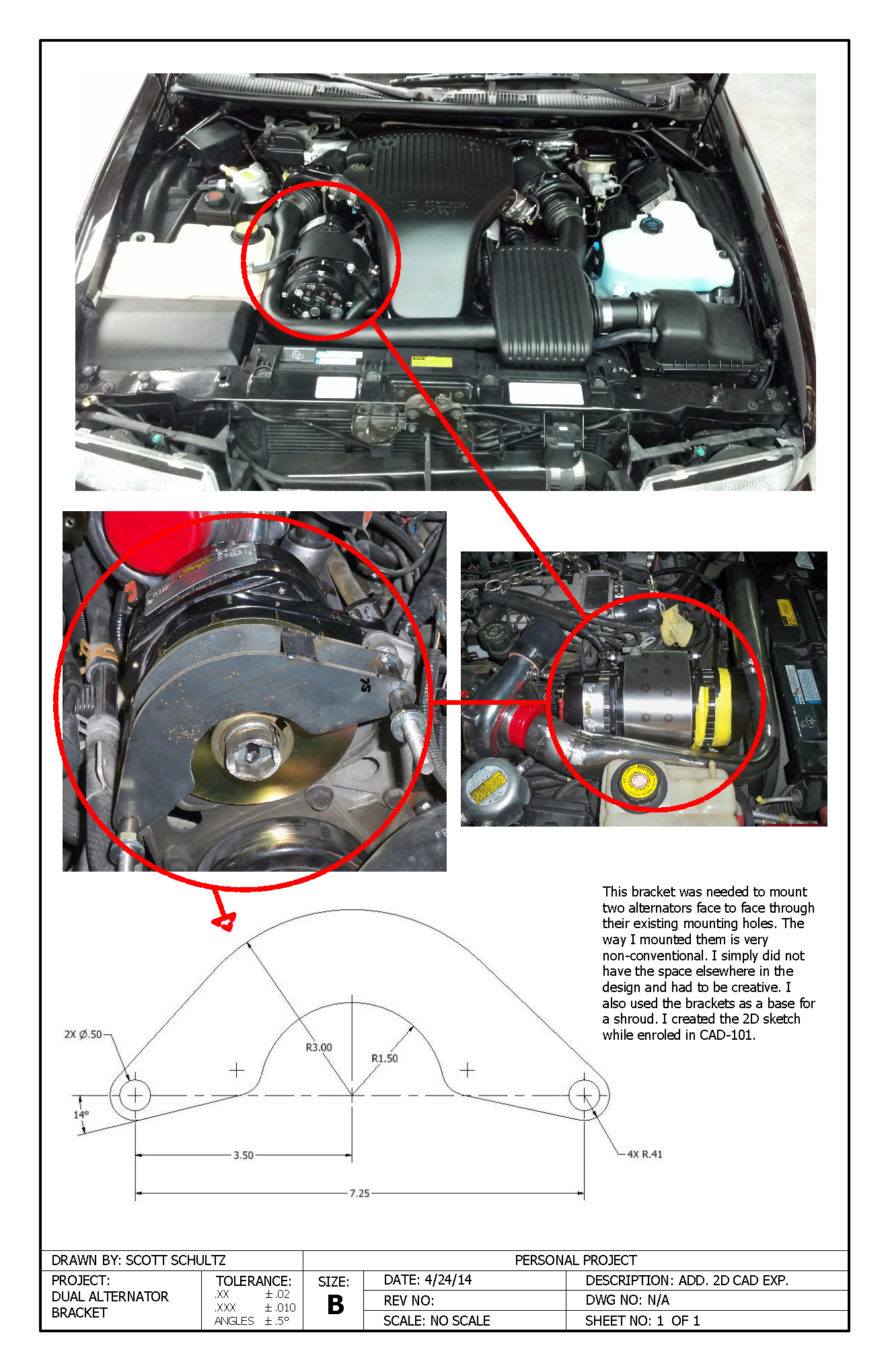

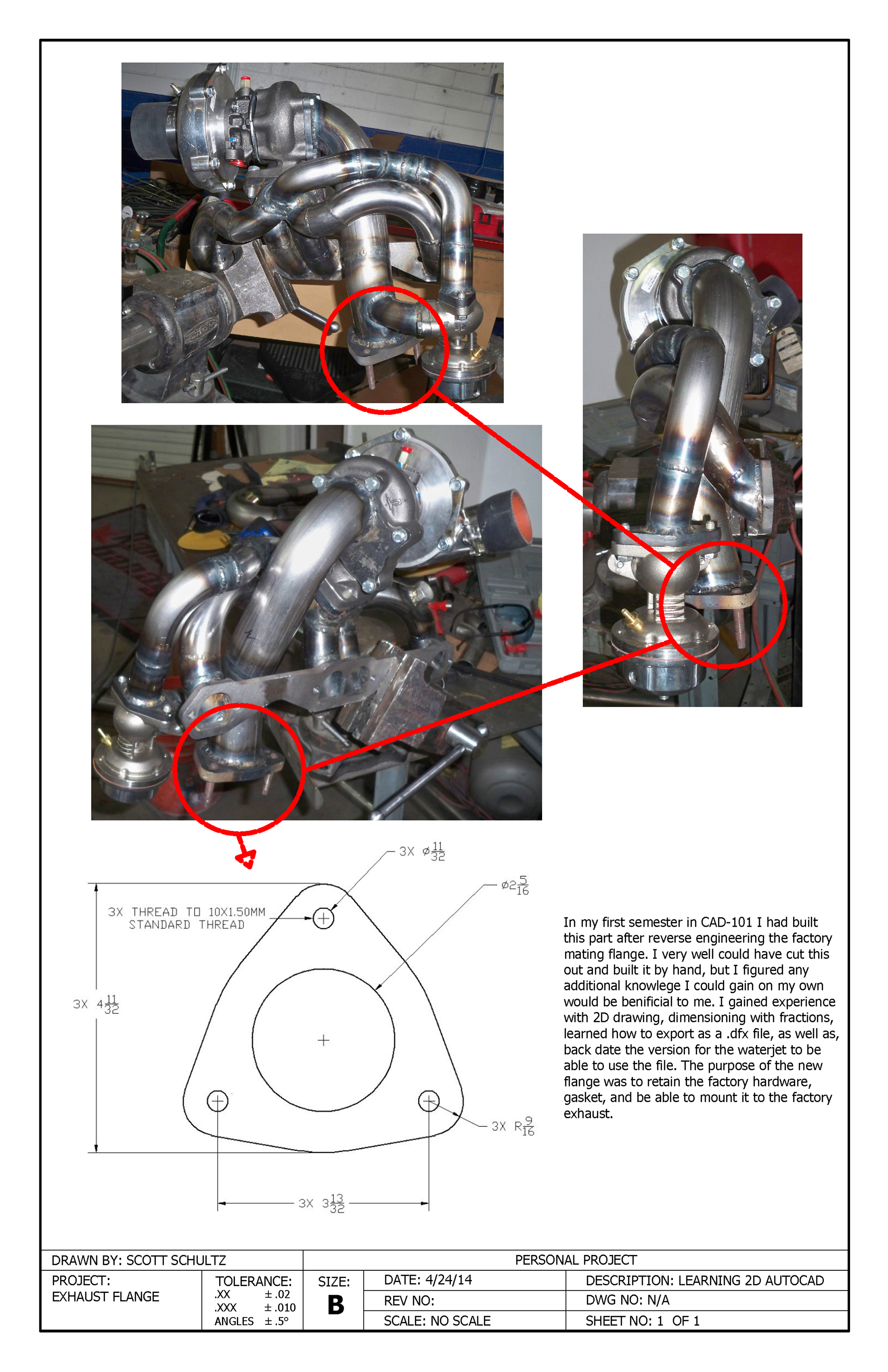

Below was some of my first applications of learning CAD while in my certificate program. I used Autodesk AutoCAD, and Inventor Pro to 3D model and send parts to a waterjet for cutting.

Below consists of a reverse engineering project that applied GD&T (General Dimensioning & Tolerancing), based on the ASME Y14.5-2009 standard, as well as, an exploded trolley assembly with call outs.